Maximizing the Potential of Etchant for Stainless Steel 304 in Metal Fabrication

The manufacturing landscape for stainless steel 304 has evolved dramatically, driven by increasing demand for precision, durability, and aesthetic appeal. Central to achieving high-quality finishes and intricate designs in metal fabrication is the judicious application of specific chemicals — notably, the etchant for stainless steel 304. This specialized compound plays a critical role in achieving desired surface characteristics, enhancing decorative features, and preparing the material for subsequent processes. At Goldeco Steel, a leading name in metal fabricators, our expertise underscores the strategic importance of using the right etchant for stainless steel 304 in various industrial applications.

Understanding Stainless Steel 304 and Its Industrial Significance

Stainless steel 304 is the most widely used grade of stainless steel, prized for its excellent corrosion resistance, formability, and easy maintenance. Composed predominantly of iron, with around 18% chromium and 8% nickel, it offers a resilient surface suitable for diverse applications — ranging from architecture and kitchenware to medical devices and precision instruments.

Its widespread adaptability makes stainless steel 304 a preferred choice among metal fabricators. Whether for creating complex decorative designs, functional components, or structural parts, understanding how to work with this alloy, especially through surface treatments like etching, unlocks its full potential.

The Critical Role of an Etchant for Stainless Steel 304

An etchant for stainless steel 304 is a chemical solution designed to systematically remove material from the surface of the metal to achieve precise decorative, functional, or preparatory effects. Proper etching enhances the appearance, creates contrast for artistic patterns, or prepares the surface for further treatments such as coating or welding.

The use of such etchants is vital in industries where surface aesthetics and detailed precision are paramount — including jewelry making, architectural panels, signage, and custom industrial components. Optimizing the etching process yields sharper designs, cleaner finishes, and increased corrosion resistance by eliminating surface contaminants.

Types of Etchants for Stainless Steel 304

Several types of chemical solutions are used as etchants for stainless steel 304, each tailored to specific needs:

- Chemical Etchants: Acid-based solutions, such as ferric chloride, nitric acid, and hydrochloric acid, are widely employed for precise and controlled etching.

- Electrochemical Etching: Utilizes electrical current to accelerate the material removal process, ideal for detailed patterning.

- Laser Etching: While not a chemical etchant per se, laser technology complements chemical methods to achieve intricate designs.

For metal fabricators focusing on traditional chemical etching, understanding the extensive options available allows for customizing processes that suit specific project requirements, whether for decorative purposes or functional surface treatments.

Key Factors in Choosing the Right Etchant for Stainless Steel 304

Selecting an appropriate etchant for stainless steel 304 depends on several considerations:

- Material Compatibility: The etchant must effectively react with stainless steel 304 without causing undue damage or pitting.

- Desired Finish: Whether matte, polished, or patterned, the etchant's aggressiveness influences the final appearance.

- Process Control: The consumable's stability and ease of handling affect process precision and safety.

- Environmental and Safety Factors: Eco-friendly options or those with minimal hazardous by-products are increasingly preferred.

- Application Scope: Whether for small-scale artistic projects or large industrial productions influences the choice of etchant type and concentration.

Industry-standard solutions, such as ferric chloride-based etchants, often balance effectiveness with safety, making them popular among metal fabricators aiming for high-quality results.

Best Practices for Using an Etchant for Stainless Steel 304

Maximizing the benefits of etching involves following established best practices to ensure precision, safety, and surface integrity:

- Surface Preparation: Clean the stainless steel thoroughly to remove oils, dirt, and other contaminants for uniform etch patterns.

- Proper Masking: Apply resistant coatings or masks to areas that should remain unetched, enabling detailed designs.

- Controlled Application: Use appropriate immersion times, temperatures, and agitation to achieve consistent etching depth.

- Temperature Management: Maintaining optimal temperature enhances reaction consistency and safety.

- Post-Etching Cleaning: Rinse thoroughly to eliminate residual chemicals and inspect the surface for quality assurance.

These meticulous steps ensure the surface quality meets industry standards and aesthetic expectations, helping metal fabricators achieve superior outcomes.

Applications of Etchant for Stainless Steel 304 in Industry

The versatile nature of the etchant for stainless steel 304 makes it indispensable across a broad spectrum of industries:

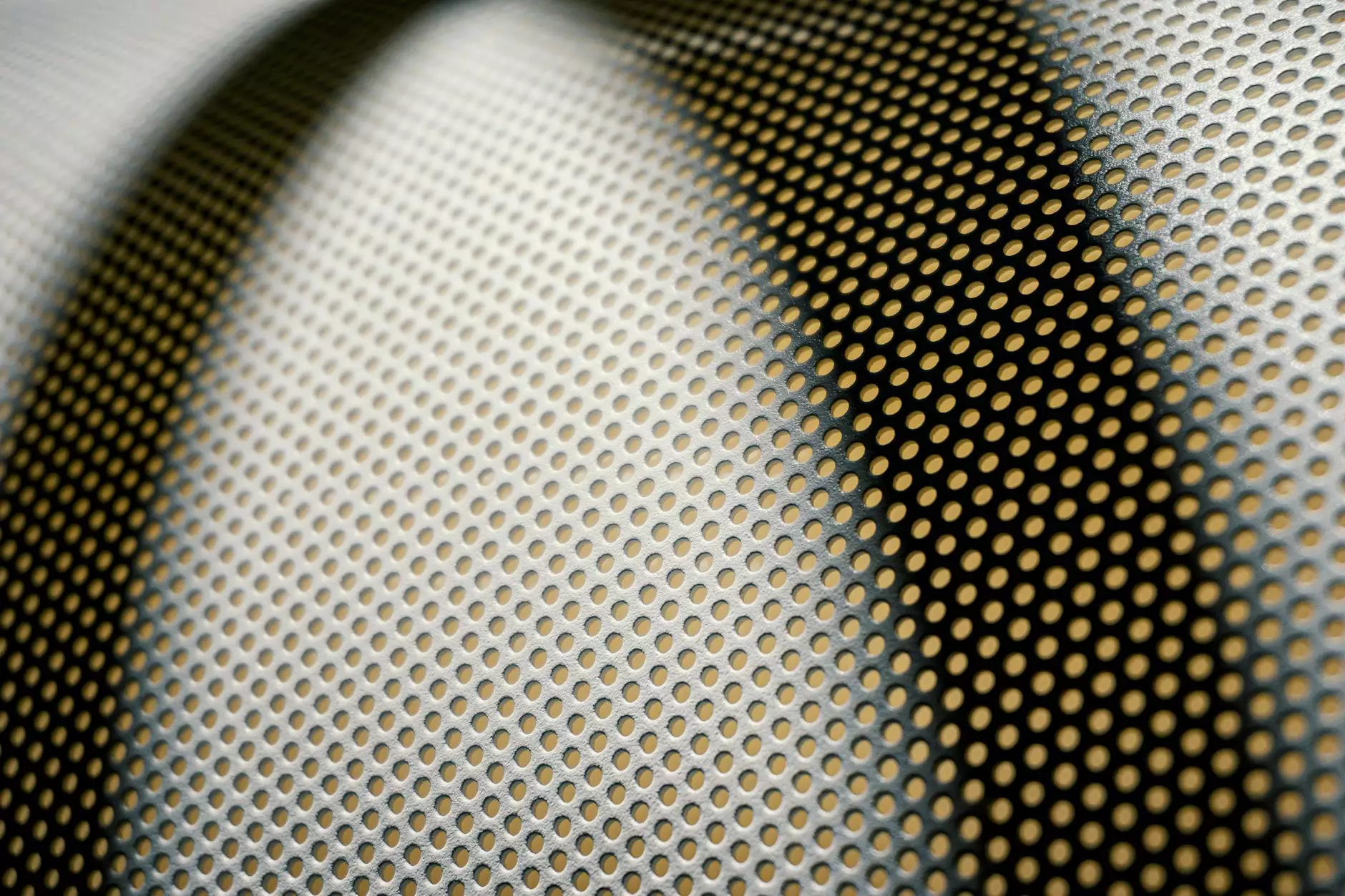

- Decorative Architectural Panels: Creating textured or patterned surfaces that enhance aesthetic appeal and fade-resistant finishes.

- Jewelry and Art Works: Producing intricate engravings and designs with high precision.

- Signage and Nameplates: Etching logos and lettering for durable, professional displays.

- Medical Devices: Ensuring smooth, clean surfaces conducive to sterilization and biocompatibility.

- Industrial Components: Marking, identification, and surface preparation for welding and assembly.

Integrating precise etching techniques elevates product quality, enhances brand differentiation, and contributes to long-term durability in these applications.

Choosing Goldeco Steel for Metal Fabrication Excellence

When it comes to selecting a partner for metal fabrication, Goldeco Steel stands out with our expertise, state-of-the-art facilities, and commitment to sustainability. Our focus on utilizing high-quality etchant for stainless steel 304 ensures that every project not only meets but exceeds industry standards.

As specialists in metal fabricators, we provide tailored solutions that combine advanced chemical etching techniques with comprehensive post-processing services. Our dedication to innovation guarantees that your projects benefit from both aesthetic excellence and structural integrity.

Whether you require decorative panels or complex industrial components, trust Goldeco Steel to deliver results that position your business ahead of competitors.

Future Trends in Etching and Surface Treatment of Stainless Steel 304

The field of surface treatment for stainless steel continues to innovate, focusing on safer, more environmentally friendly solutions. Emerging trends include:

- Nano-etched Surfaces: Achieving precise micro or nano patterns for cutting-edge applications like sensors and biomedical devices.

- Green Etching Technologies: Developing biodegradable and less hazardous chemicals to minimize environmental impact.

- Automation and Digital Controls: Integrating computer-controlled etching processes for unparalleled precision and reproducibility.

- Multi-functional Surface Treatments: Combining etching with coatings that confer additional properties like self-cleaning, anti-corrosion, or antimicrobial activity.

Staying abreast of these advancements enables metal fabricators and manufacturers to provide innovative solutions that elevate their product offerings and operational efficiencies.

Conclusion: Unlocking the Full Potential of Your Stainless Steel 304 Projects

The successful application of an etchant for stainless steel 304 is pivotal in achieving high-quality, aesthetically pleasing, and durable surface finishes. By understanding the types of etchants available, selecting suitable products, and adhering to best practices, metal fabricators can vastly improve their craft and meet the evolving demands of their clients.

Goldeco Steel’s expertise and commitment to excellence make us the ideal partner for all your *metal fabrication* needs. We provide tailored surface treatment solutions that enhance the performance and appearance of stainless steel 304 components, ensuring your projects stand out in a competitive marketplace.

Invest in the right etching processes today to unlock the full potential of stainless steel 304 — transforming raw materials into masterpieces of durable beauty and functional excellence.